How does it work?

GFC uses supercritical carbon dioxide as its primary solvent

and sc-CO2 is fundamentally more efficient than using traditional organic solvents in Flash Chromatography.

Supercritical carbon dioxide is a powerful yet environmentally friendlier solvent substitute.

It has both the density of a liquid and the properties of a free-flowing gas, making it an ideal chromatography processing solvent in place of liquid organic solvents. Supercritical CO2 has some level of tunable polarity to solvate and separate polar mixtures for therapeutic drug development.

Recent research indicates that the addition of chaotropic modifiers show greater separation promise by decreasing the net hydrophobic effect of solute hydrophobic regions, improving solubility in sc-CO2 by denaturing analytes.

Want to know more about how G-Flash can advance your chromatography processes?

| Traditional Flash Chromatography | G-Flash |

| Requires expensive solvent purchase, storage, handling equipment, and disposal fees. | Significant cost savings through the reduction in organic solvent requirements. |

| Limited solvation capability of traditional flash including peptides and biomolecules. | Superior solvation power of a supercritical fluid suggests it may be able to perform separations not currently possible with traditional flash chromatography. |

| Arduous workflow and slow residual evaporation times. | Greater laboratory productivity through streamlined workflow and reduced evaporation time. |

| Health and Safety for employee exposure to solvents that are toxic, flammable, carcinogenic, and often neurotoxins. | Small amounts of co-solvents used are generally alcohols that are safer than the solvents commonly used in traditional flash chromatography. |

Chromatography

Traditional flash chromatography has significant limitations

both in its capabilities and the impediment it presents to efficient workflow in the laboratory. For example, as therapeutic peptides become increasingly important in drug development, a better method to perform crude separations is essential. Pertinent scientific literature demonstrates the ability of supercritical fluid chromatography (SFC) to perform some separations of peptides, and this will be an area of investigation for GFC in the near future.

Peptide drugs are essential molecules in the pharmaceutical industry with a multiplicity of therapeutic properties, such as being anti-hypertensive, anti-microbial, anti-diabetic, and having anticancer potential. In the area of SARS-Covid research, over 50 peptides are known to inhibit SARS-CoV-1. This is a critical area of research.

Examples of traditional small molecule flash separations with the GFC platform are below.

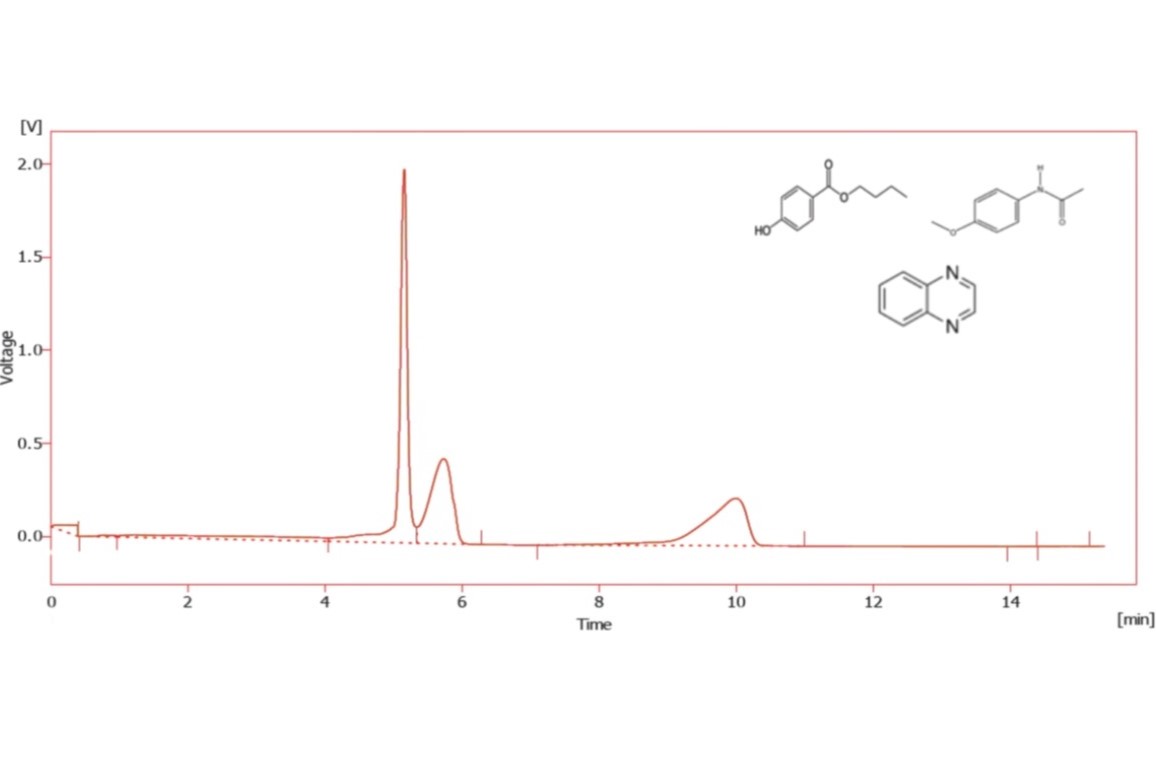

Butyl Paraben, Quinoxaline, and 4′-Methoxyacetanilide

Dimethyl Phthalate and Dipropyl Phthalate

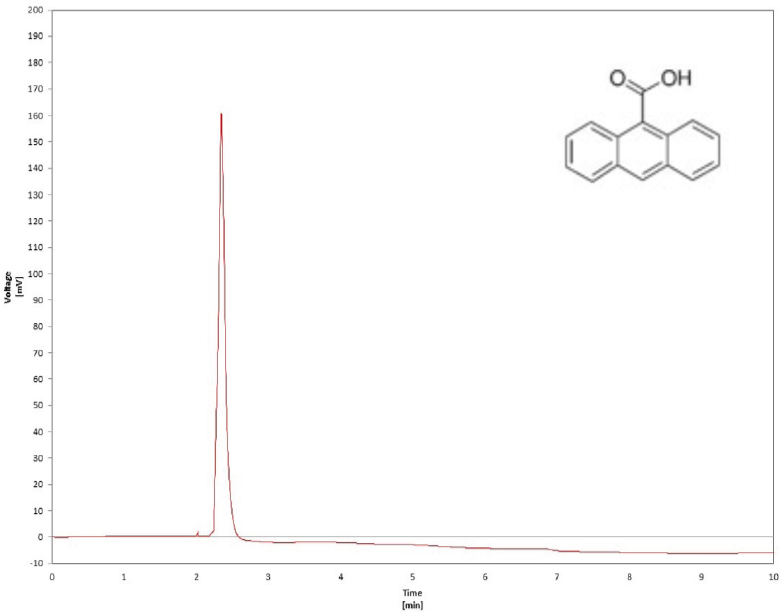

9-anthracene

p-anisaldehyde

Specifications & Requirements

GFC Specifications

- Joule Thompson, subzero cooled, precision sc-CO2 and cosolvent pump heads for a total 1.0 to 75.0 ml/min range of process method flow

- Cosolvent addition pump compatible with the most traditional polar mobile phase eluents such as methanol, ethanol, and ethyl acetate

- Pressure Containment Assembly (PCA) with cartridge antileak technology allowing for the use of traditional plastic. Flash Chromatography cartridges at the pressures required for sc-CO2 Flash Chromatography

- Automatic SC-CO2 and cosolvent gradient programming precision control for method runs ranging from 2 to 60 minutes

- Data acquisition powered by Clarity software platform for chromatogram capture, data manipulation, and analyte separation

- 22” Touch Panel PC that seamlessly merges system control and data acquisition in a sleek design

- 200 – 600 nm Scanning PDA UV detector that measures up to four wavelengths simultaneously

- Gas-liquid separator for less than 5% analyte loss from aerosol overspray and less than 2% dispensed analyte crosscontamination between runs

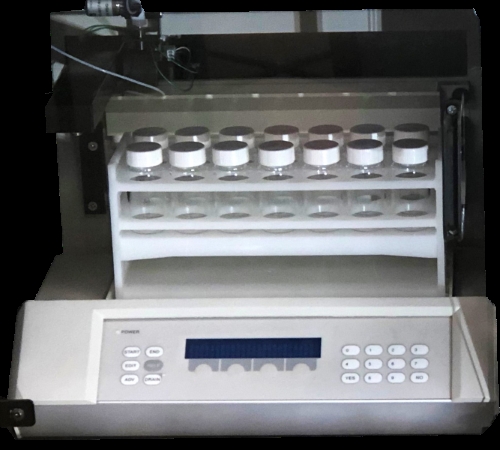

- Automatic eluate/analyte separation dispensing gantry with mobile phase waste management

- Weight and Dimensions: 140 lbs – 24″ x 24″ x 30″ (64 kg – 61cm x 61cm x 76cm)

- Onboard filtration and polishing system enabling use of commercial grade CO2 dip tube for liquid delivery cylinders (nominal 850 psi, tank heaters as needed)

Utility Requirements

- 230VAC single phase, 20 amps, 50/60Hz

- Nitrogen cylinder (3,000 psi or higher)

- Liquid CO2 cylinder with dip tube or bulk equivalent

- Ventilation for CO2 and solvent exhaust (connection to a 2” outlet)

Patents

G-Flash LLC has been awarded several patents for the key advances that protect the underlying technology essential to GFC platform. These patents are effective in the US, the EU, and additional jurisdictions worldwide. They include:

US Patent 10,765,968: “System and Methods for Supercritical Fluid Chromatography”

US Patents No 10,610,808 and 11,680,735: “Supercritical Fluid Chromatography System”

US Patent 11,022,350: “Cooling Loop with a Supercritical Fluid System using Compressed Refrigerant Fluid Flow with a Positive Joule-Thompson Coefficient.”

US Patent Application No. 17/416,964: “Interchangeable Chromatography Cartridge Adapter System” – Notice of Allowance

US Patent Application No. 18/485,807: “Gas Liquid Separator (GLS) for collection of sample eluent” – In process

Additional provisional patent filings are underway covering various technological advances for GFC platform